WHY CHOOSE KMP?

Quality ASSURED -QUALITY department

Why Choose KMP Brand Products: Unmatched Quality Assurance

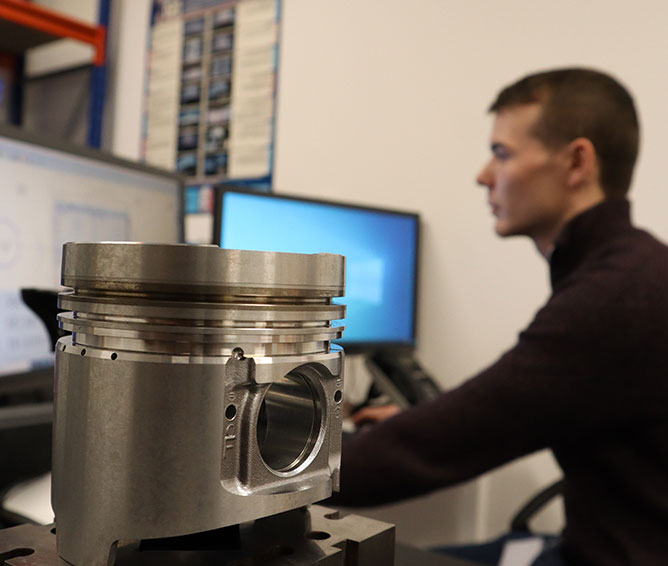

Discover why discerning customers consistently turn to KMP Brand products. Our commitment to excellence shines through our unparalleled quality assurance processes, ensuring that every KMP Brand part exceeds expectations.A Wealth of Expertise

At KMP Brand, our Quality Department boasts an extensive repository of meticulously developed and rigorously approved drawings and samples. This invaluable resource forms the cornerstone of our commitment to precision. We frequently consult this repository alongside our expansive OEM Store, guaranteeing that every KMP Brand component adheres flawlessly to specified standards.Elevating Standards: A Focus on Precision and Reliability

Our exacting quality control procedures stand as a testament to our dedication to excellence. Every single component undergoes rigorous scrutiny to ensure it meets our stringent specifications for reliability. We take immense pride in our ISO certification, a testament to our unwavering commitment to maintaining the highest industry standards.

The following detail a selection of the metrology techniques and equipment used by KMP throughout the development and quality control process.

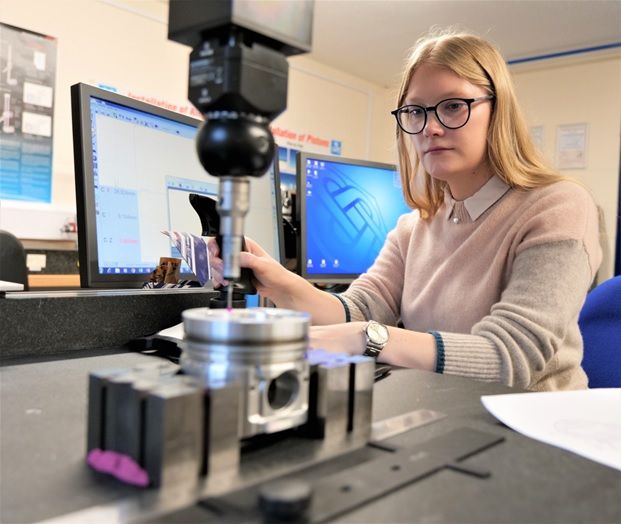

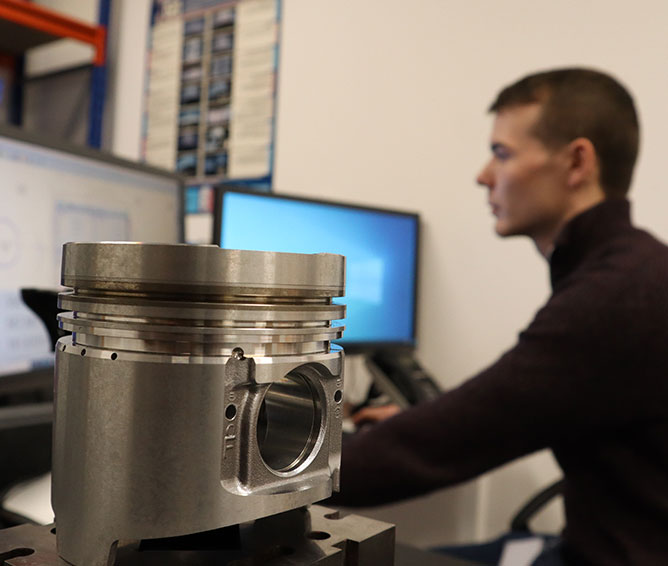

CO-ORDINATE MEASURING MACHINE (CMM)

The CMM is used to measure the geometry of our parts using various probes. This machine can measure down to a resolution of 1 micron and is used to measure many parts including pistons, ring gears, crankshafts, camshafts and rollers.

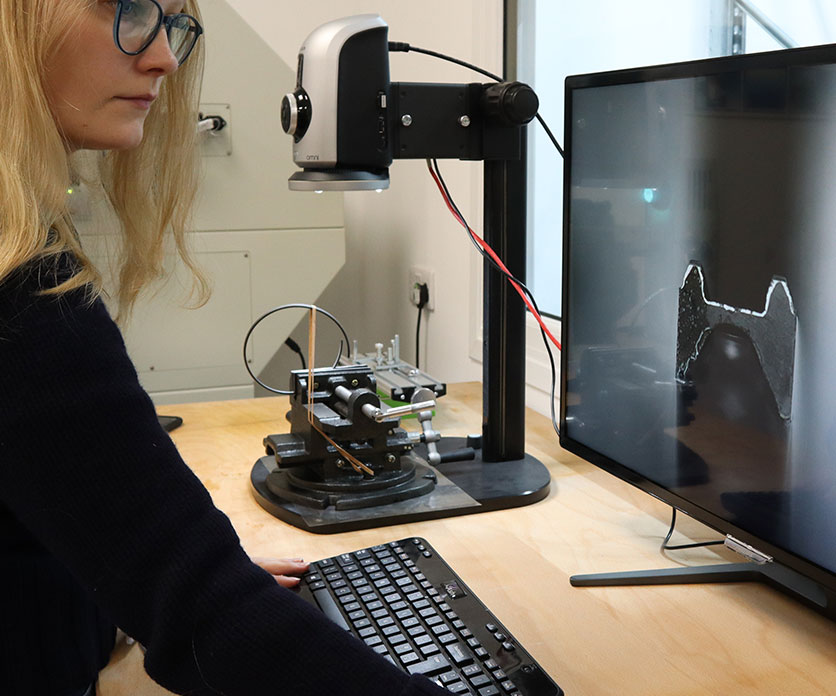

DIGITAL MICROSCOPE

The digital microscope can zoom up to 160x and is invaluable in the measurement of bearing material thickness, coating analysis (piston rings) and failure/crack analysis.

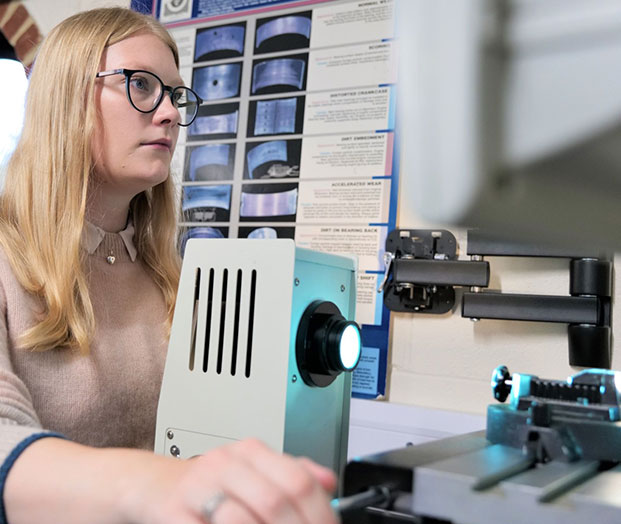

SHADOWGRAPH

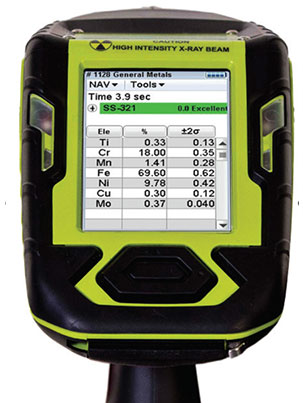

XRF Analyser

- The latest addition to the KMP Quality Department is our new XRF Analyser, which determines the elemental composition of the material of a part through non-destructive spectroscopy.

- All OEM parts can be tested using the XRF Analyser in order to the material specification to be identified. This information can be used in development to ensure that our parts will perform to the same standard as the OEM material.

- Any KMP part failures can be fully analysed using the XRF Analyser to ensure that we maintain our high standards throughout our parts.

Tangential Tension Tester: Piston rings

The Tangential Tension Tester is used to measure the tension force of piston rings, a critical step in our quality control process. Accurate tension ensures the ring will maintain proper contact with the cylinder wall, directly affecting engine performance and reliability. Ensuring the tension is correct when developing a piston ring is essential within the drawing approval procedure and helps confirm that each piston ring meets the required specifications and will perform consistently with OEM standards. By verifying tension at this stage, we reduce the risk of failure and ensure that every ring we supply delivers the fit, seal, and function our customers expect.

ROCKWELL HARDNESS TESTER

All hardened components are tested using either a Leeb Hardness Tester or the Rockwell Hardness Tester.

A Rockwell Hardness Tester is used to measure the hardness of materials, specifically how resistant a material is to deformation under load.

Multiple measurements are taken on each part to confirm that hardening has been applied correctly and consistently across critical areas. This process is essential for parts such as valves, piston pins, cam followers, crankshaft and camshaft journals, valve seats, and more – components where durability and wear resistance are key to performance.

LEEB HARDNESS TESTER

SURFACE FINISH MACHINE

The Surface Finish Machine allows us to test the quality of the surface of rollers, and test liners to ensure they have the correct grooves for oil retention. These components operate under constant friction, so achieving the correct surface finish is critical to engine performance and longevity.

A smooth, properly finished surface helps reduce wear, improve sealing, and ensure efficient operation inside the engine. Using precise measurements we verify that the liners and rollers meet the required standards – minimizing friction and extending service life.

Watch how we inspect and control surface quality to make sure every component performs exactly as it should.

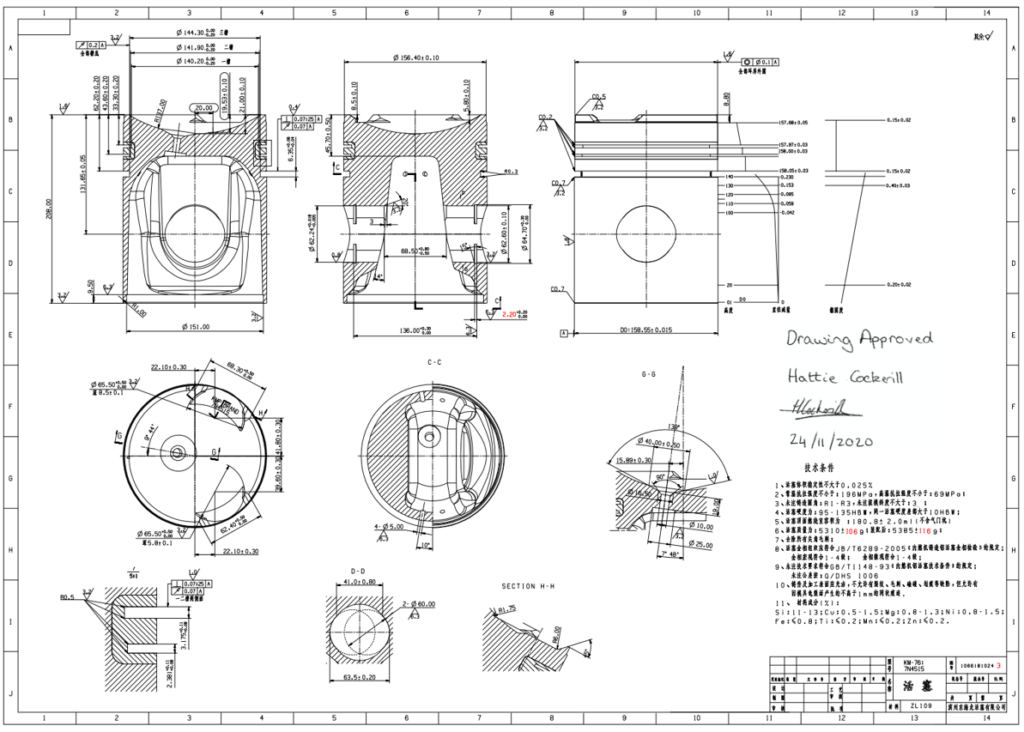

KMP BRAND PISTON DRAWING

DIGITAL VERNIER HEIGHT GAUGE

CRANKSHAFT AND CAMSHAFT ANALYSIS

DIGITAL MICROMETER

DUROMETER SHORE A

KMP Brand’s library of approved designs and samples is in constant evolution, with over 400 parts currently in active development. This dynamic growth mirrors our continuous pursuit of innovation and our drive to offer an ever-widening selection of premium parts.

Precision through Comparison: Reverse Engineering for Excellence

WHAT WE DO BEST

Technical Support

Our knowledgeable and experienced technical support team can assist with enquires about all our parts.

Quality Parts

We are dedicated to the quality of all KMP Brand parts. Since 2003, we have held ISO 9001 certification for the production & distribution of diesel engine components.

Manufacturing

We manufacture all KMP Brand to the highest standards, assuring that every stage of the development process results in an affordable product with no compromise on quality or reliability.

Sourcing

The key to delivering quality parts has been an efficient supply chain. With our years of experience and extensive knowledge of the industry, we always ensure that our inventory can meet the growing demand.

Distribution

The head office and distribution centre is conveniently situated in Chertsey, England. This location provides easy access from central London and is only a short distance from the UK’s premier airport – Heathrow. In addition we have subsidiary companies located in the USA, Singapore and Malaysia.